Magnefine Filtration

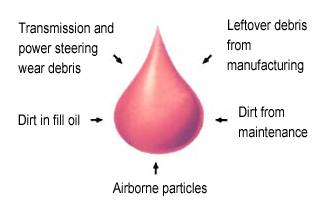

All transmission and power steering system oil becomes contaminated during normal use, and needs proper filtration. Automatic transmissions and power steering systems continually generate millions of harmful, microscopic metal particles, through normal wear and tear. Even the best flushers cannot remove all these metal particles. Consequently, even when new oil is introduced, it will pick up these harmful, left-over particles, immediately re-creating the wear and tear induced by the old oil. Electronically controlled transmissions and power steering systems will suffer extensive (and expensive!) damage to valve bodies and solenoids because of these metal particles in the oil. Prevention is the only sensible solution... and the cheapest. (Today an automatic transmission or power steering system overhaul costs thousands of Rands.) The revolutionary new Magnefine, Magnetic In-Line Filter helps to prevent expensive automatic transmission and power steering system damage.

Why filter?

The filter is designed to remove harmful contamination from hydraulic fluid. This allows the fluid to perform the designed function of transmitting force, lubrication and cooling.

Oil and other hydraulic fluids become contaminated during regular use.

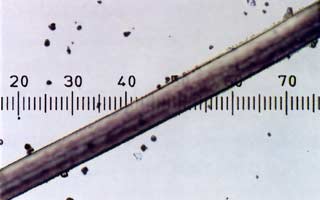

Magnefine removes abrasive particles down to 3 microns and less. The average human hair is 75 micron!

Modern transmissions perform as an integrated part of the vehicle power train system. Transmissions now feature sophisticated electronic components that allow the vehicle's management system to control gearshifts, lock-up converters and applications that will affect all aspects of the vehicle configuration and duty cycles. Electronic components and complexity comes at additional cost and is contaminant intolerant. When the system fails warranty costs are high.

THE CHAIN REACTION OF WEAR

Particle caught

Surface cracked

Crack spreads

Surface fails, more particles released

During normal operation of the engine, particles get caught between precisely machined moving parts. This causes damage to the metal surface of the parts. Particles are shaved off the metal surfaces, which causes more particles to come free. These particles in turn cause more damage.

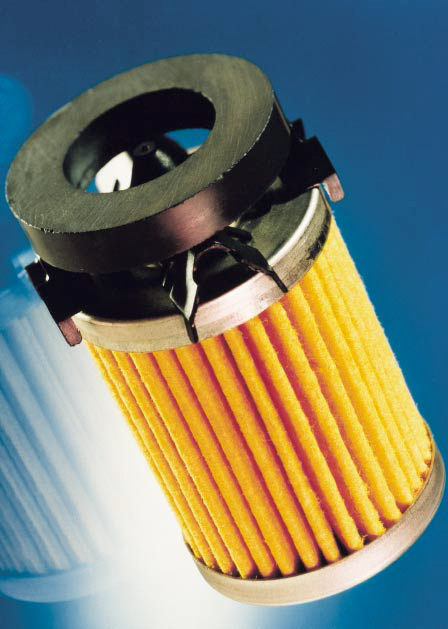

Standard oil filters contain felt or cellulose paper membranes. These membranes contain pores that are small enough to stop the larger contaminants. The smaller particles however pass freely through the pores of the filter. This allows minute but highly damaging metal particles to remain present in the fluid and cause damage to the engine.

Dual Filtration

The Magnefine system is covered by worldwide patents. It is used by OEMs in Europe USA, Africa, Middle East, Asia and Australia. Professional transmission repairers worldwide install over one million filters on rebuilt transmissions and power steering units. Fleet operators appreciate Magnefine labour savings at service and how it extends transmission life. Any vehicle which puts extra load on a transmission should use Magnefine. This includes towing, 4x4 applications, heavy loads, stop start driving; taxis, fleets or where extended life of the transmission is desired.

Complies with ISO 9002 Standards.

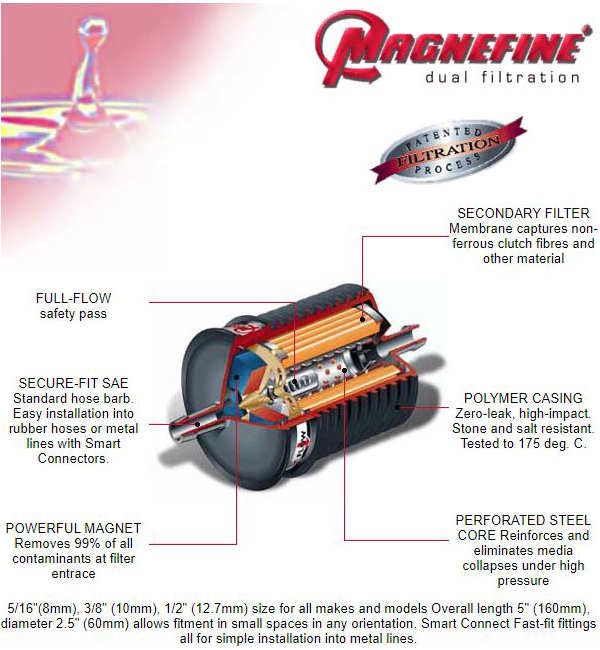

The Magnefine Full Flow Filter features dual filtration.

First, a patented magnetic process removes all damaging wear metal particles, irrespective of size. Second, a pleated paper element combines to extract the non-ferrous contaminants. The result is your fleets lubricating fluid will be cleaner and perform better for more kilometers.

- Power magnet - removes 99% of wear metal contaminants at filter entrance

- Full-Flow safety bypass

- Secondary Filter Membrane - captures non-ferrous clutch fibres and other materials

- Secure Fit - SAE-standard hose barb. Easy installation to rubber hoses or metal lines with Smart Connect

- Polymer casing - zero leak, high impat, stone and salt resistant

- Perforated steel core - reinforces and eliminates media collapse under high pressure surges

Power Steering

Has your power steering ever been serviced?

When was the last time your car service included your Power Steering?

Don't bother checking your cars service book. You won't find power steering listed on any of the pages. You have to specifically ask for the job to be done. The simple reason for this is that power steering has only recently became a popular option and is not usually included as part of regular maintenance. Yet industry surveys indicate that regular servicing could have prevented 90% of power steering failures. That's not all you can save. Today's hi-tech power steering systems can cost from R1800 to as much as R8500 to repair or replace.

Warning signs to watch for

If your steering has "hard" spots or is becoming less responsive, a drive belt could be slipping or a control valve could be jamming. If you find a few drops of oil where your car was standing overnight, a worn seal could be allowing the systems lubricating fluid to escape. These are danger signs that you can't afford to ignore, because they could be prelude to a total and unexpected failure of your power steering.

A frightening experience

If suddenly the pump fails, a hose bursts or a drive belt breaks, the results can be frightening. It's as if some outside force has seized control of your steering wheel. It takes tremendous effort to move it even half a turn. You can still control your car, but only just. The last place you want something like that to happen is in busy traffic or on a winding mountain road.

Service every 12mths/ 20000km

Along with your brakes, engine and suspension, your power steering system needs to be serviced regularly. Every 12 months or 20,000 kilometers, take it to a qualified Automotive Technician for a comprehensive safety check and adjustment, including replacement of the power steering fluid and Magnefine filter.

Why the fluid and Magnefine filter need changing

The reasons are exactly the same for replacing your engine oil and oil filter during every service. Whenever your engine is running, the friction between the moving parts continually produces microscopic metal particles. As the days and weeks and months roll by, these build up in their millions. As you can imagine, it is essential that the filter traps these ferrous and non-ferrous abrasive contaminants in the lubricating oil, before they can cause damage. However, there comes a time when both the oil and the filter must be changed if your engine is to be protected to maximum effectiveness. The same is true for your power steering fluid and filter. You can ensure that the system continues to operate safely and effectively.

How to keep power steering safe and trouble-free

Regularly check the level of your power steering fluid and top it up if necessary. Your owner's manual will tell you where to look. When checking the level of the fluid, also check the colour. If it darkens, seek professional advice. Check for oil spills on your driveway. Never hold the steering on full lock for more than 4 seconds. If you do, you can damage the pump. Avoid turning the wheel when your car is stationary. This puts unnecessary strain on the entire steering system. Have strange noises checked out immediately. Have "hard" spots, hesitations or any free-play in the steering wheel checked as soon as possible.

Automatic Transmission

How it works for you

New Vehicles:

Install the Magnefine inline filter on the OUTLET LINE (flow from the transmission to the cooler) when the transmission is NEW. This will protect the whole transmission and cooler system from contamination build-up and extend the fluids useful life.

Retrofit Your Fleet:

At your regular P.M. service, install Magnefine into the RETURN LINE (from cooler to the transmission). This will clean the existing system from contaminants.

Every 30,000 miles:

Drain (if pan drain plug installed) or evacuate the fluid and change the Magnefine in-line filter, then refill the system. It is not necessary to touch the pan or the pan filter, unless for mechanical concerns.

Fleet analysis: failed transmissions

Tear-down analysis of 3229 failed transmissions demonstrates the reason for failure:

- 29% of failures were related to restricted cooler flow and pan-service concerns

- 71% were for other concerns

Exchange Transmissions:

- 26% of exchange transmissions failed within 12 months or 12,000 miles due to cooler restriction, stuck valves and solenoid malfunction as a result of excess contamination

General Filtration

Filters play a major role in preventive maintenance sales.

Every mechanical component of today's car, truck and SUV has one common enemy: dirt. Whether produced internally by the combustion process or brought in from outside, dirt is the number one cause of engine, power steering and automatic transmission breakdown. Effective filtration plays a key role in preventing unnecessary wear and premature failure. Modern filters are more effective than ever before, when it comes to preventing damage to the engine, power steering, automatic transmission and fuel system. However, they are only effective when replaced on a regular basis. There are different types of filters for various applications. We will be generalising in this article.

Air filters

Between 10,000 and 12,000 gallons of air are needed for today's trucks and cars to burn 5 liters of fuel. Dirt equivalent to the size of two aspirin tablets within that air will cause the same amount of wear as 90,000 kilometers of normal driving. With that in mind it's easy to see how important air filters are. Without a quality air filter, dirt, road grit

and other debris can "sand blast" internal engine parts, carburetors and fuel injectors.

Engine oil filters

At 80 Kph just over 1000 litres of oil flow through an engine every 60 minutes. After 7,000 kilometers, the 8 to 10 liters of oil in today's cars pass through the engine 15,000 times. If the oil is contaminated, that is 15,000 chances to cause damage to the main bearings, camshafts, crankshafts and numerous other engine parts. A neglected oil filter is a sure way to kill and engine.

Power steering and ATF

According to the Automatic Transmission Rebuilders Association almost 9 out of 10 automatic transmission failures are due to overheating, fluid contamination or oxidisation. Like motor oil, automatic transmission fluid (ATF) suffers from heat, friction and electro-chemical breakdown which causes it to lose its lubricating and protective qualities.

Once this starts, sludge and varnish begin to form within the transmission. At the same time bits of transmission friction material as well as metal particles may be floating in the ATF and clogging the pan filter which does not have any by-pass valve built in to it. When they clog, the transmission is starved for lubrication which can cause shifting problems or produce a whining sound. The metal particles can also be attracted to the electromagnetic solenoids and cause jamming. Most modern vehicle ATF pan filters are made of polyester felt, capable of only removing particles as small as 60-200 micron.

The Magnefine filter

The Magnefine filter, when fitted properly, will remove ferrous and non-ferrous, hard metal wear particles that grind away at the softer brass components particles. This will extend the useful life of the fluid, and stop the chain reaction of wear (whereby wear particles increase wear, which in turn increase the amount of wear particles).

By doing this you also get longer life and use of the power steering assemblies and automatic transmission. Typical power steering and automatic transmission lubrication tolerances are between 5-15 microns (the width of a human hair is 70 microns). The Magnefine Dual Filtration (magnet and paper with built in by-pass valve) filters from 3 to sub-micron, thereby giving you removal of 99.9974% of the contaminants(as per proven tests conducted by the University of Melbourne).

The better the filtration the cleaner the oil

The cleaner the oil the better it will perform!

How to install?

Either do it yourself or ask your service centre to install a Magnefine filter. There is a size to suit all makes and models of vehicles: 5/16" (8mm), 3/8" (10mm) or 1/2" (12.7mm). Simple instructions on insertion into the return cooler line are included on the pack for each vehicle make.

When to change

Recommended change is every 12 months. It is also advisable to renew your transmission fluid at this time. In fleet applications a test by the Ford motor company demonstrated fluid and filter lifetime could be 30,000 miles. (Each transmission runs differently and may require different fluid service intervals.) At change interval you simply evacuate (or drain) the fluid from the system, change the in-line filter and refill. OEMs acknowledge it is not necessary to touch the pan up to 100,000 miles, unless for mechanical concerns. This also avoids troublesome pan related problems.

Effect my transmission performance

With clean oil all machines will run better than with dirty. Your transmission is no exception. The Magnefine filter does not restrict oil Lubrication flow. It has been tested in hot and cold conditions and approved by OEMs in Europe and USA.

No clogging

Magnefine double filtration is so efficient it removes 99% of all wear metal contaminants. Its design holds the majority of contaminants on the uniquely positioned magnet. Even if the filter element becomes full, its safety bypass opens for full flow and the magnet still cleans metal from the system.